Exclusive Japan Smart Manufacturing Tour for Industry Leaders

Join the 5 Days Immersive Japan Smart Manufacturing Tour to experience Japan’s world-leading manufacturing excellence through direct access to Toyota experts, hands-on TPS training, and cutting-edge smart factory technologies.

- 6th -10th April 2026

- Nagoya & Toyota City

Japan Smart Manufacturing Tour Highlights

Strategic Insights for Decision-Makers

TPS Dojo Training

The

Toyota Production System (TPS)

was built on a powerful philosophy: eliminating every form of waste to achieve the highest level of operational efficiency. Its origins go back to the pioneering automatic loom created by Sakichi Toyoda, and it was further shaped through decades of experimentation and improvement. Kiichiro Toyoda later advanced these ideas into the Just-in-Time concept, forming the foundation of modern Lean manufacturing and transforming how the world views productivity.

During this programme, you will learn inside Toyota’s official TPS Dojo. Through hands-on model-line simulations guided by veteran Toyota instructors, you will gain a practical understanding of Kaizen, Jidoka and waste elimination.

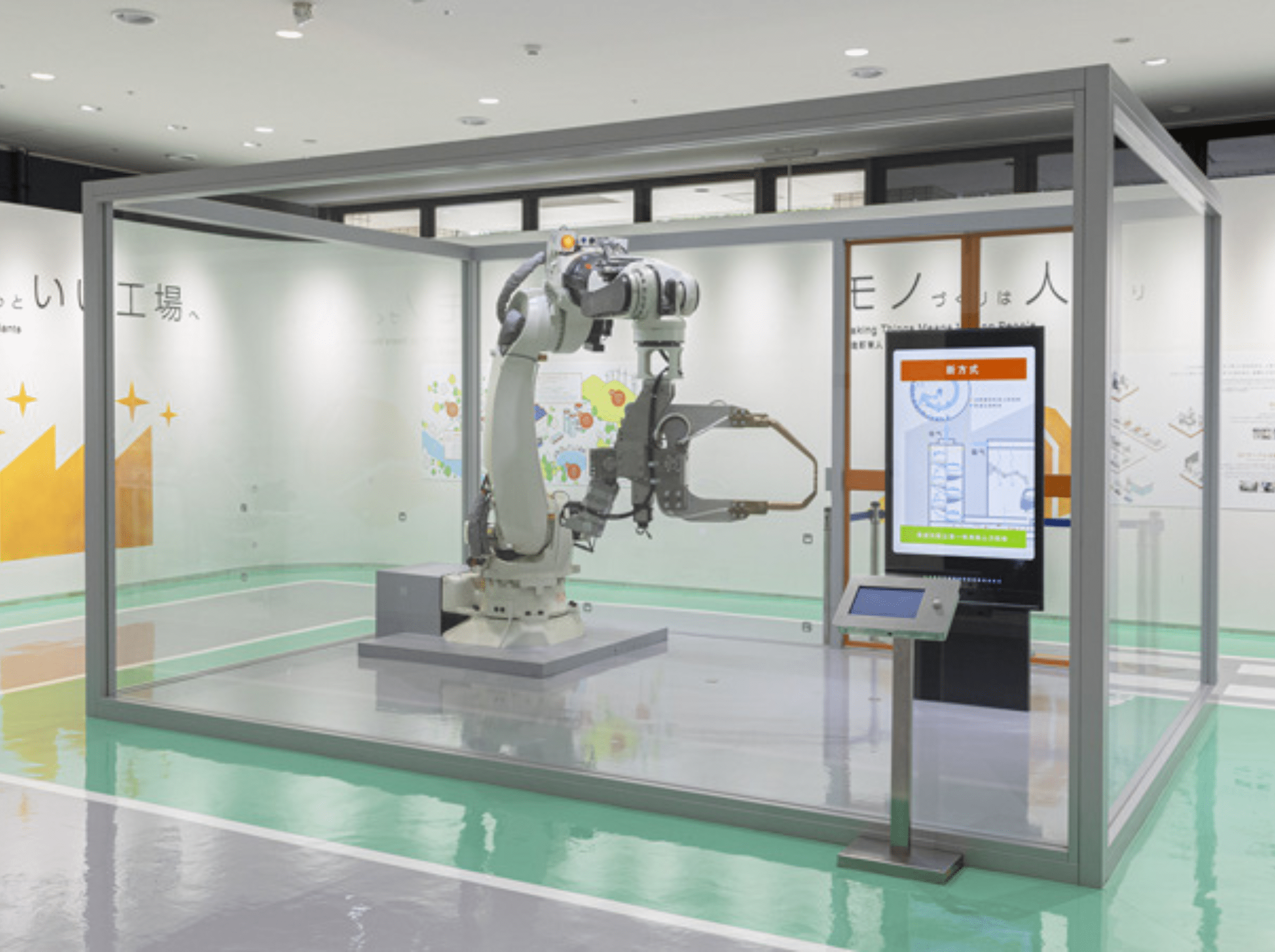

Mitsubishi Electric

Smart Manufacturing Excellence

Experience Japan’s leading smart factory showcasing advanced automation, robotics, and energy-efficient production. Learn how Mitsubishi Electric achieves world-class quality, zero-defect culture, and operational excellence through innovative technology and disciplined processes.

Shin Nippon Koki

Precision Engineering & Lean Culture

Discover a high-performance manufacturing environment built on Lean principles, precision engineering, and strong workforce discipline. See real applications of 5S, waste elimination, and visual management that drive efficiency, quality, and continuous improvement.

Manufacturing World Exhibition

Port Messe Nagoya, Japan

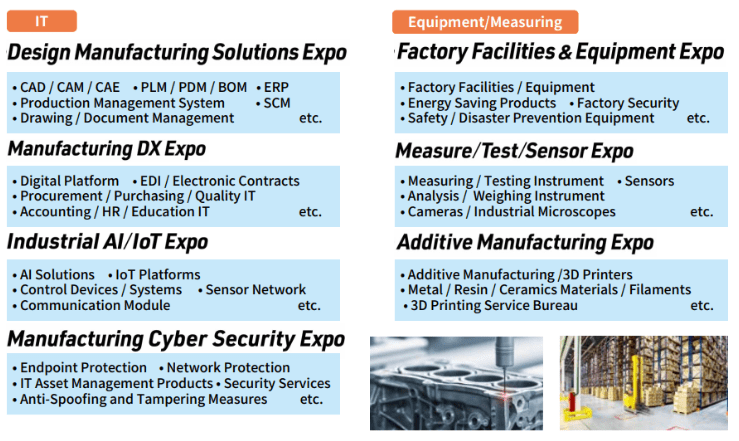

Manufacturing World is a leading exhibition showcasing mechanical components, motion technologies, DX solutions, additive manufacturing, factory equipment and advanced measurement instruments. This event provides an exceptional opportunity to discover new ideas.

Explore 650+ exhibitors presenting the latest in Automation, DX technologies, Additive Manufacturing, Smart Factory Systems and Cybersecurity solutions, making it a powerful benchmarking platform for organisations pursuing next-level operational excellence.

Experience the Essence of Japan

Experience the essence of Japan beyond the factory floor, from witnessing the beauty of seasonal cherry blossoms that symbolise precision and perfect timing, to rejuvenating through traditional Japanese onsen wellness practices that restore focus and clarity, and exploring Nagoya’s cityscape where rich heritage, modern urban life, and industrial innovation seamlessly converge.

Who Should Attend

- CEOs, Directors & Senior Leaders

- Operations, Production & Manufacturing Managers

- HR & Organizational Development Specialists

- Quality, Lean, and Continuous Improvement Teams

- Engineers & Future Leaders

If you oversee operations, manufacturing, productivity or are responsible for organisational transformation; this tour is made for you.

OVERSEAS SEMINAR & CONFERENCE HRD Claimable

Turn this tour into an investment, not a cost. As a registered training programme under HRD guidelines, Japan Smart Manufacturing Tour qualifies for HRD claims, making world-class learning accessible and affordable for Malaysian companies.

FAQ: Smart Manufacturing Tour

Yes. This overseas programme is eligible under HRD Corp, Overseas Seminar and Conference.

This enables Malaysian employers to develop critical talent capabilities aligned with Lean, Kaizen, and Smart Manufacturing transformation.

Several premium features set this tour apart, especially the presence of Lean Expert, J. Ramesh Victor, who will accompany the entire journey to translate TPS principles into practical Malaysian applications. Participants will also receive guided learning inside the official TPS Dojo, gain access to Toyota Kaikan Museum and Toyota Village, and experience smart factory innovations and robotics showcases. The programme culminates with a full-day immersion at Manufacturing World Nagoya, making this a curated learning experience.

The programme is capped at 25 participants to ensure a high-value, personalised learning experience for each organisation.

Both SMEs and large enterprises benefit from this tour.

SMEs gain practical ideas that can be implemented immediately, while larger organisations benchmark strategic transformation models used in Japan’s top manufacturers.

Many Malaysian manufacturers struggle to interpret Lean correctly because they have never experienced a real-world benchmark of the Toyota Production System.

Automation adoption often progresses slowly, cultural discipline for continuous improvement is difficult to instil, and transformation plans lack clarity without a proven reference model.

Through the Japan Smart Manufacturing Tour, leaders finally gain firsthand exposure to TPS in its original environment, allowing them to understand how world-class factories operate, why their systems consistently achieve high performance, and what principles can be adapted to strengthen operations back home.

By witnessing authentic practices in Toyota City and other advanced facilities, participants return with sharper confidence, clearer direction, and actionable insights to drive meaningful change within their organisations.

Ready to Build a World-Class Manufacturing Culture?

Bring home the discipline, precision, and innovation Japan is renowned for. This is more than a trip, it’s a transformational experience for your business.